HPCLJCP1510Repair

| HP CP1515n Color Calibration Status: stable | |

|---|---|

| |

| Beschreibung | Fix Color Calibration of HP CP 1515n Printer |

| Autor: | omicron |

| Version | 1.0 |

| PayPal | |

Objective

The objective of this project is to fix a HP LaserJet CP 1510 Series printer having color calibration issues.

Short version

Problem

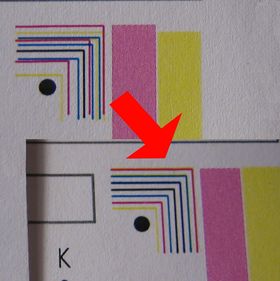

- Color calibration of a HP Color LaserJet 1510 Series Printer (e.g. CP 1515n) is not working correctly (see top left part of image)

- All attempts to fix the problem otherwise have failed:

- Update to latest firmware

- Repeated calibration (> 3 times)

- NVRAM reset

- Reset to Factory defaults from menu

- The following other attempts were not done:

- Replace the ITB assembly (cost reasons)

- Buy set of original HP toner (cost reasons)

Solution

Common

- Print diagnostics page using the printer menu (for later comparison).

- Get the service manual (Google for "HP Color Laserjet CP1215 CP1515 CP1518 Service Manual")

- Follow the instructions for removing the Intermediate Transfer Belt (ITB)

Part 1: Trimmer

- Turn the ITB assembly upside down

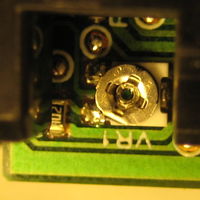

- Find the two small PCBs where the wires end

- Take a photo of the positions of all 3 trimmer (labelled VR1, VR1 and VR2 on the two PCBs)

- Find the trimmer labelled VR1 on the right of the two PCBs (the board with 2 trimmers on it). Example:

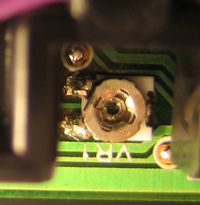

- Turn VR1 clockwise. For me, 90 degrees worked. However, the calibration seems to be quite sensitive to the exact position. Hence you have do some trial-and-error here. Example:

- Follow the instructions of the service manual for re-installing the ITB assembly

- Connect printer to power

- Start a color calibration

- Print diagnostics page and compare with diagnostics page before the fix

- Done (or try another trimmer position)

- If no trimmer position works, see long version

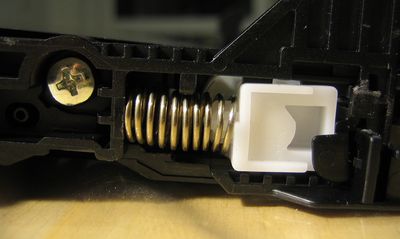

Part 2: Springs

- Remove one spring on each side of the ITB board. The following picture shows one of them in assembled state:

- The springs are only fixed on one end. The other end (the left end in the above picture) can simply be levered out using a big screwdriver.

- Afterwards, use two pairs of pliers for stretching the springs. This is done for the purpose of increasing the spring stiffness.

- It may be sensible to turn the pliers while stretching the spring for preventing an increase or decrease of the diameter of the spring.

- Afterwards reassemble the springs. This may be a little bit tricky and took me some minutes: I used two screwdrivers: One for tensioning the spring and putting it into the right place and another smaller screwdriver for stripping the spring from the first screwdriver - while pulling the first screwdriver out and leaving the spring in its place.

Notes

- This fix will certainly break warranty. Hence, only do it with printers being out of warranty!

- The fix proved to work for a single CP1515n printer. It may have to be modified for other instances.

- If changing VR1 on right PCB does not solve the problem, try the other trimmers (But always remember the original state!)

- When testing the effect of changing the trimmer, you only need to reassemble the following components

- The ITB itself

- The print-cartridge drawer stop

- The Print-cartridge drawer

- The left cover for your own safety, because the high voltage components are located beneath it

- But (as always) be careful not to touch any live parts when the printer is connected to power!

- Instead of stretching the springs, you can of course replace them by a new one. However, it must be replaced by a spring with the appropriate length, stiffness and diameter, which most people (including myself) do not have at hand.

Long Version

Note that, if nothing else is mentioned, after each change I started calibration (at least, but usually only) twice.

Unfortunately, the short version worked only once. When I changed VR1 (see above), I also tightened the screws of the ITB. Hence there was a chance, that not the change of the trimmer led to success but the tightening of the screws. Hence, I changed back the trimmer to its original position and reassembled the printer. Then, as expected, the calibration failed again. Now I changed again the trimmer position as mentioned above and again reassembled the printer. Unfortunately, it did not work this time: Even after 3 calibrations the "L-lines" in the diagnostic page crossed each other.

Because of the above experience, I then supected a mechanical problem. Hence, I tightened the screws again. This time I used a special torque screwdriver and tightened all screws of the ITB module (which I could reach) with 1 Nm. Unfortunately, this did not help either.

My next attempt consisted of 4 things (I was quite in despair):

- I temporarily dismounted the front top part of the ITB and remounted it afterwards without doing any real change.

- I dismounted the two coil springs which seem to tighten the belt and stretched them with two pairs of pliers - for the purpose of increasing the spring stiffness (in a very amateurish way)

- I again turned all 3 trimmers in the exact position where the calibration initially worked

- I dismounted the 2 PCBs and removed the plastic covers covering the component side and cleaned them (for details see below)

After reassembling everything again, it worked again.

Now I again wanted to know, which change was the successful one (i. e. was it the cleaning of the PCB or some mechanical change), I turned the trimmer back to its original position. Now the calibration failed again. But after carefully turning the trimmer again into its known-working position, calibation was successful again.

Finally, I did some sensitivity analysis of the calibation working or not for various trimmer positions. During this analysis, at some point it did not work again. I then only increased the spring stiffness (again) without changing anything (apart from the "good" VR1 position). Afterwards, it worked again.

Then I inspected the mechanism which tightens the belt a little bit more carefully. From the beginning on, I noticed two rather loose plastic parts near the springs, which function I could not identify. After having reassembled the springs I noticed that they have to do with the tightening mechanism. The two plastic parts are levers to relax and tighten the ITB. However, I did not found any information about this feature in any document - neither the printer manual nor the service manual! Additionally, this tightening mechanism can be accessed even if the printer is fully mounted - with only the front door open (TODO: pictures!). Hence, it may have been enough to relax and re-tighten the ITB after re-assembling the printer instead of having to increase the spring stiffness at all! The re-tightening might increase the fit of the ITB assembly inside the printer.

Hence the original problem seems to have 2 causes:

- The spring stiffness of the ITB springs or the correct fit of the ITB in reassembled state

- The position of VR1

Finally, I did some sensitivity analysis of successful calibration to the positions of the 3 trimmers - starting from the now hopefully well-reproducible good position of VR1.

As it turned out, I obviously initially hit the correct trimmer position of VR1 by chance: The trimmer position needs to be in a range of about +/- 5-10 degrees to be optimal, i. e. leading to a correct calibration.